Project Description

Sandwich Panel for Boat Interiors

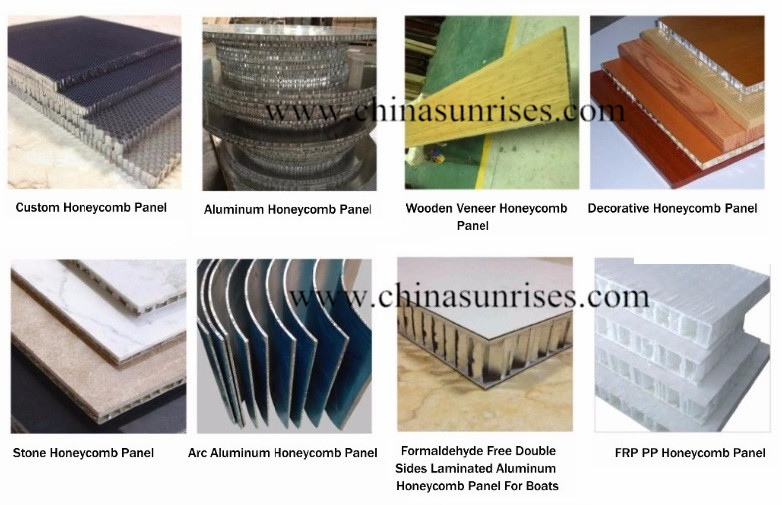

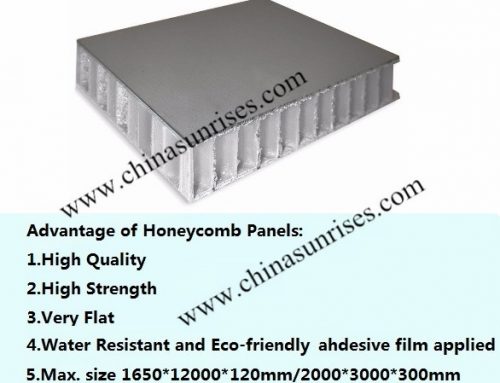

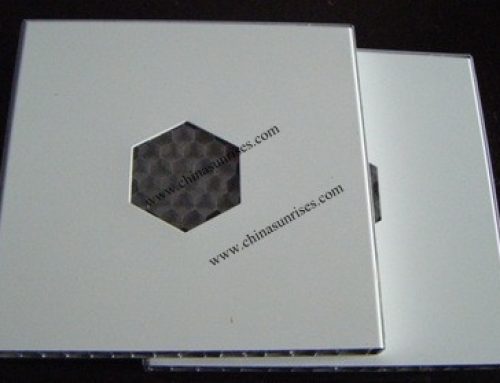

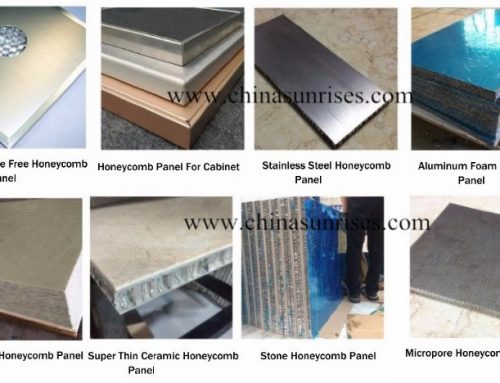

The aluminum honeycomb panel is made of honeycomb core, surface aluminum panel and bottom aluminum panel adhesive with environmental protection glue. Its main materials are high-quality of 3003H24 or 5052AH14 aluminum plates with thickness of 0.8-1.5mm for surface panel and 0.6-1.0mm for bottom panel. The patterns can be stone, marble/granite/ceramic, wood veneer/bamboo veneer, stainless steel, fiberglass (FRP), etc.

Usually, the surface aluminum panel is treated by PVDF coating or PE coating. PVDF(Polyvinylidene Fluoride) coating is suitable for outdoor because of its good properties of anti-weathering, anti-contamination and self-cleaning. Due to Polyester(PE) paint’s great nature, it can achieve versatile vivid color and higher gloss rate than PVDF. It is ideal for interior wall, decoration and signboard materials. You can save much cost.

Specification

| Usage | Indoor/Outdoor | Function | Fireproof, Sound Insulation, Anti-Corrosion |

| Aluminum Alloy | A1101, A3003, A5052 | Surface Treatment | PVDF/PE Coating (or per requests) |

| Foil Thickness | 0.02-0.1mm | Hole Type | Regular/Micropore/Slant |

| Top Panel Thickness | 0.1-2.0mm | Bottom Panel Thickness | 0.1-2.0mm |

| Max. Width | 2300mm | Size | Allow big sizes |

| Color | Depends on customer’s requests | Pattern | Wood/Stone/Bamboo/FRP(or per requests) |

| MOQ | 100 SQM/Color | Lead Time | 3-15 days after sample approval |

| Guarantee | 15-30 years | Certificates | ISO9001, SGS, MA, ilac-MRA, CNAS |

Honeycomb Core Index

| Side length | Incircle Diameter | Foil Thickness | Max. Expanded Size (W*L) | |

| mm | mm | inch | mm | mm |

| 0.6 | 1.016 | 1/25 | 0.02 | 300×500 |

| 1 | 1.588 | 1/16 | 0.03/0.04 | 1000×1000 |

| 1.5 | 2.540 | 1/10 | 0.03/0.04 | 1200×1500 |

| 1.83 | 3.175 | 1/8 | 0.04 | 1600×2000 |

| 0.06 | 1600×1600 | |||

| 2 | 3.175 | 1/8 | 0.04 | 1600×2000 |

| 0.06 | 1600×1600 | |||

| 2.5 | 4.233 | 1/6 | 0.04 | 1600×2200 |

| 0.06 | 1600×2000 | |||

| 3 | 5.080 | 1/5 | 0.04 | 1600×2400 |

| 0.06 | 1600×2200 | |||

| 0.08 | 1600×2000 | |||

| 0.10 | 1600×1800 | |||

| 4 | 6.350 | 1/4 | 0.04 | 1600×3100 |

| 0.06 | 1600×2400 | |||

| 0.08 | 1600×2200 | |||

| 0.10 | 1600×2000 | |||

| 5 | 8.467 | 1/3 | 0.04 | 1600×4000 |

| 0.06 | 1600×3000 | |||

| 0.08 | 1600×2200 | |||

| 0.10 | 1600×2000 | |||

| 6 | 9.525 | 3/8 | 0.04 | 1600×4600 |

| 0.06 | 1600×3600 | |||

| 0.08 | 1600×2800 | |||

| 0.10 | 1600×2400 | |||

| 7.5 | 12.7 | 1/2 | 0.04 | 1600×6000 |

| 0.06 | 1600×4000 | |||

| 10 | 19.05 | 3/4 | 0.04 | 1600×7500 |

| 0.06 | 1600×5000 | |||

| 12 | 20.32 | 4/5 | 0.04 | 1600×9000 |

| 0.06 | 1600×6000 | |||

| 15 | 25.4 | 1 | 0.04 | 1600×12000 |

| 0.06 | 1600×7500 | |||

| 20 | 34.925 | 1.375 | 0.04 | 1600×15000 |

| 0.06 | 1600×10000 | |||

| 30 | 50.8 | 2 | 0.04 | 1600×20000 |

| 0.06 | 1600×15000 | |||

Features

Excellent Rigidity & Strength

Lightweight & Energy-Saving

Fireproof & Waterproof

Heat & Sound Insulation

Moisture & Corrosion Resistance

Easy to Install & Maintenance

Super Flatness and Rigidity

Environmental-Friendly

Good Thermo Stability with Temperatures up to 350°

* Please contact us for final confirmation on above data before you place order.